From Particle Filtration to Heavy-Duty Chemical Splash: Your All-in-One Industrial Barrier Solution.

- Protective Clothing

Premium Type 3/4/5/6 Protective Coveralls | Advanced Flash-spun HDPE Protection for Global Industries.

Understanding PPE Protection Standards: Type 3, 4, 5, and 6 Explained

Type 3 (EN 14605): Liquid-tight protection against pressurized chemical jets. Found in our TC300 model.

Type 4 (EN 14605): Spray-tight protection for intensive liquid spray. Featured in TC300 with hot-melt stitched seams.

Type 5 (EN ISO 13982-1): Protection against hazardous dry particles and dust. Available in TC300, TC400, and TC500.

Type 6 (EN 13034): Limited protection against light liquid splashes. All models meet this standard.

Biological Protection (EN 14126): Our TC400 is specifically designed for infectious disease prevention and animal epidemic control.

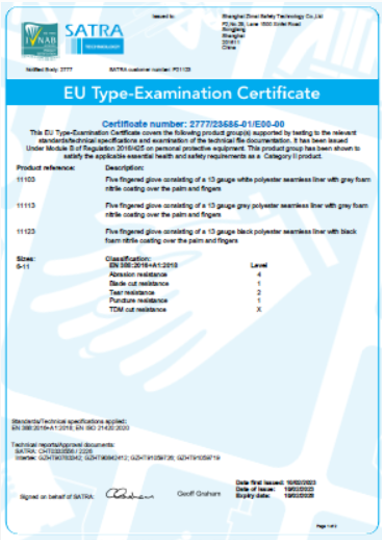

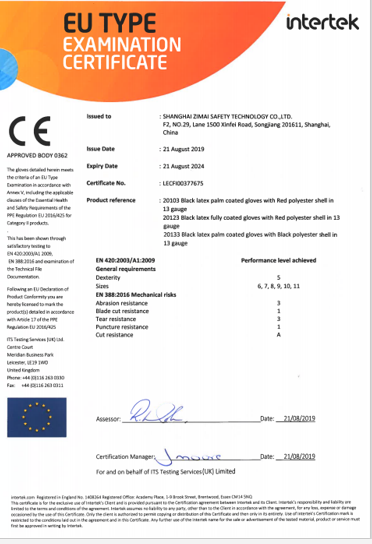

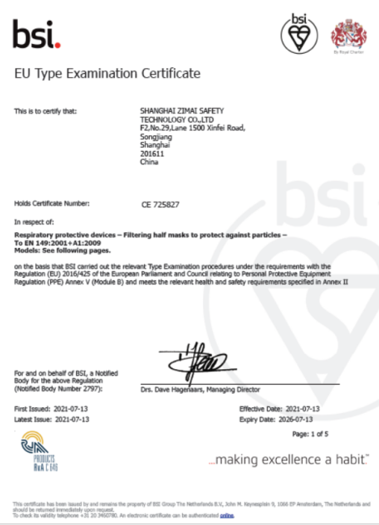

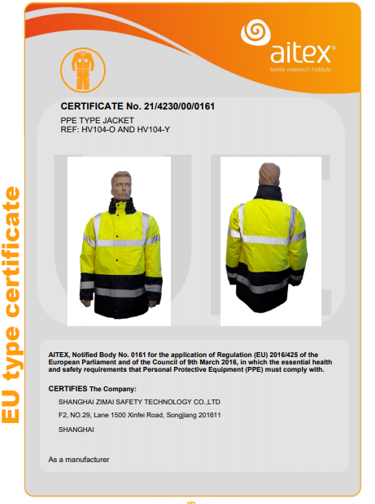

Certified Excellence in PPE Manufacturing

Advanced Material Technology: We utilize premium Flash-spun HDPE non-woven fabric, offering a unique balance of high-strength durability and breathable comfort.

Full Standard Compliance: Our facility and products are fully CE Certified, strictly adhering to EU PPE standards including:

EN 14126: For protection against biological infectious agents (Featured in TC400).

EN 14605: For liquid-tight and spray-tight chemical protection (Featured in TC300).

EN 1149-5: Anti-static performance for explosive environments.

EN 1073-2: Protection against radioactive particulate contamination.

Industrial Grade Sealing: All safety-critical models (TC300 & TC400) feature hot-melt taped seams to ensure zero-leakage at every stitch.

Product Comparison

| Feature | TC300 (Industrial Flagship) | TC400 (Bio-Hazard Specialist) | TC500 (General Purpose) |

|---|---|---|---|

| Material | 87gsm Flash-spun HDPE | 45gsm Flash-spun HDPE | 45gsm Flash-spun HDPE |

| Protection | Type 3B, 4B, 5B, 6B | Type 5B, 6B | Type 5B, 6B |

| Seam Type | Yellow Hot-melt Taped | Blue Hot-melt Taped | Basic Stitched |

| Anti-static | Yes (EN 1149-5) | Yes (Both sides) | Yes (Both sides) |

| Best For | Chemical mixing, Pesticide spraying | Hospitals, Customs, Vector control | Paint spraying, Food processing |

Why Partner with Our Factory?

- Quality Assurance: All products are CE Certified and comply with rigorous EU standards (EN 14126, EN 1073-2).

- Customization (OEM/ODM): We offer sizes from S to 4XL and custom branding options for B2B clients.

- Global Supply: Dedicated to supplying hospitals, customs, and industrial sectors with emergency reserves.

Order & Communication Process

Do You Have A Project To Discuss ?

-

Needs Assessment And Consultation

In this initial phase, we work closely with you to identify specific workplace hazards and safety requirements. Our team analyzes your industry standards (CE, NIOSH, ISO) to define the exact PPE specifications needed for your workforce.

-

Solution Proposal And Sampling

This stage involves presenting a tailored product solution, including material selection and customization options (OEM/ODM). We provide physical samples for your team to test, ensuring comfort, fit, and full compliance before moving forward.

-

Production And Quality Assurance

Once the sample is approved, mass production commences under strict ISO quality control protocols. We maintain transparent communication throughout the manufacturing process, conducting rigorous testing to guarantee every item meets safety certifications.

-

Global Logistics And Support

The final phase ensures seamless delivery through our global supply chain network. Beyond shipping, we offer after-sales support, including usage training and streamlined re-ordering processes to keep your inventory stocked.

Exhibited Worldwide Every Year

Certifications & Compliance