Facepiece Reusable Respirator

- Products

- Facepiece Respirator

OEM/ODM Manufacturing for Full-Face & Half-Mask Respirators

We support your business with scalable production, compliant documentation, and factory-direct customization—built for long-term supply.

Half Facepiece Reusable Respirator- DR300

–TPE Facepiece:

Engineered with an adaptive TPE faceacepiece that accommodates diverse facial geometries, combining superior comfort with lightweight performance.

–Bayonet connection:

Utilizes a bayonet-style rotational locking system for universal particulate filter connectivity, facilitating swift and secure filter changes with guaranteed airtight sealing performance.

–Adjustable head strap design, fit closer to the face

–Sequential overmolding design:

Minimal-part, compact design for easy cleaning and welding helmet integration.

–Hidden exhalation valve design

Half Mask Respirator- DR600

Half Mask Respirator- DR600

–Silicone Faceseal:

Anatomically shaped silicone seal fits facial contours, withstands high temperatures, and offers biocompatible, lightweight durability.

–Bayonet connection:

Utilizes a bayonet-style rotational locking system for universal particulate filter connectivity, facilitating swift and secure filter changes with guaranteed airtight sealing performance.

–Adjustable head strap design, fit closer to the face

–Sequential overmolding design:

Minimal-part, compact design for easy cleaning and welding helmet integration.

–Cool flow and hidden exhalation valve design

Full Facepiece Reusable Respirator- DR800

FULL Mask Respirator- DR800

-Large screen:

Expansive field of vision, high-grade polycarbonate material, low-velocity impact resistance,

permanent anti-fog coatings applied to interior and exterior surfaces.

–Bayonet connection:

Bayonet-style rotary connection for broad compatibility with gas, vapor, and particulate

filters;

Tool-free installation/disassembly ensures quick filter changes and a reliable airtight seal.

–Silicone full faceseal:

Silicone faceseal adapts ergonomically to facial profiles;

Comfortable, secure, and hypoallergenic for sensitive skin;

Engineered for durability and effortless cleaning.

-Adjustable head hoop set:

Four-point silicone head hoop set with precision adjustability for secure, ergonomic comfort.

-Hidden exhalation valve design

–Optional screen film for protection

unveiling, we ensure that our designs reflect their unique needs, preferences, and aspirations.

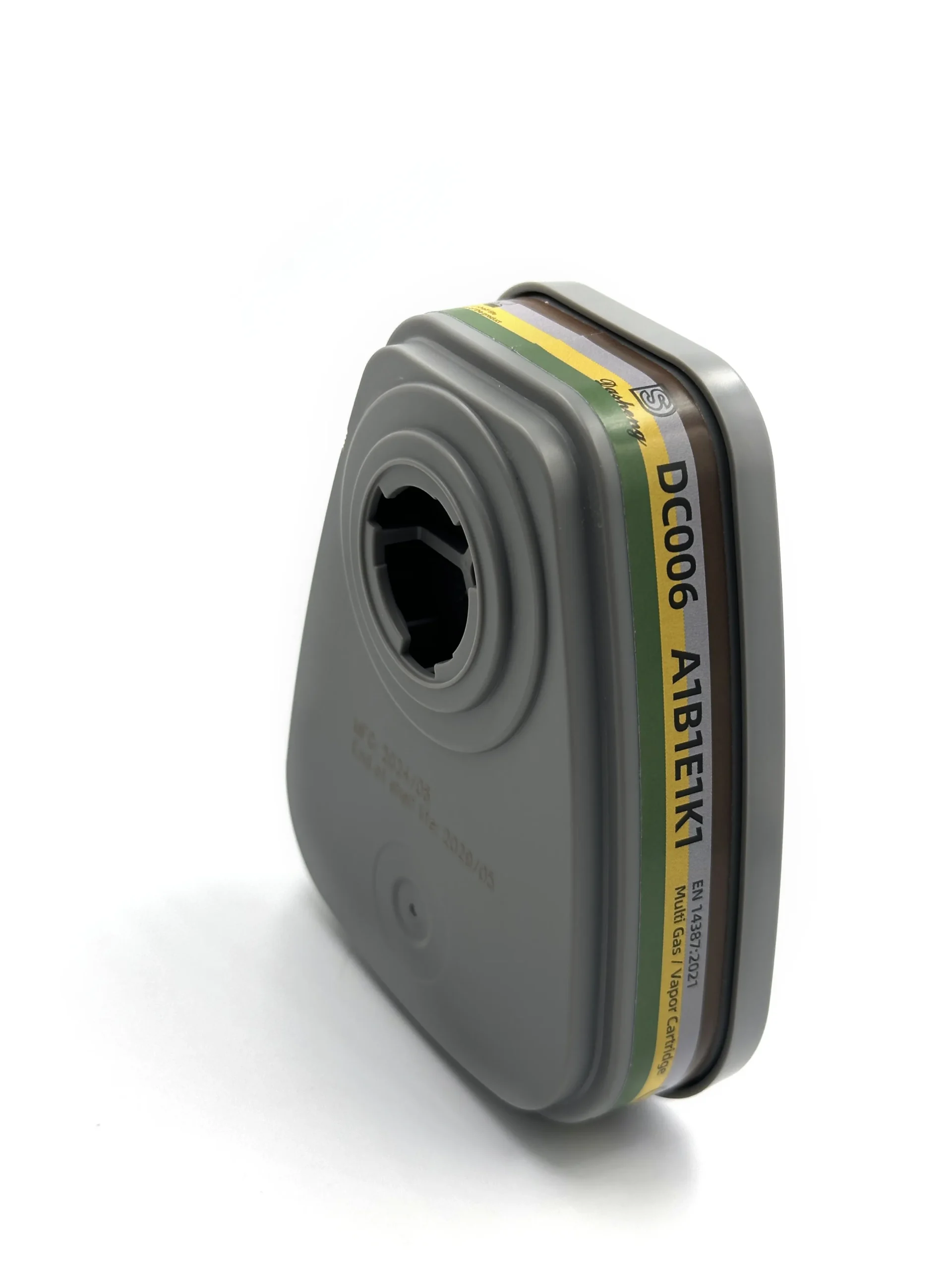

How do I know what respirator cartridge to use?

Selecting the correct respirator cartridge is the difference between complete safety and dangerous exposure. For safety officers and PPE distributors, understanding the “language” of cartridges is essential for ensuring workplace compliance. At CoSafety, we produce a wide range of universal bayonet cartridges. In this guide, we will simplify the selection process by explaining hazard types, color codes, and replacement schedules.

Step 1: Identify the Hazard Type

Before selecting a cartridge, you must determine what is in the air. Respiratory hazards generally fall into two categories:

- Particulates (Dust, Mists, Fumes): Requires a Particulate Filter (e.g., N95, P100, or FFP3). These use physical fibers to trap solid or liquid particles.

- Gases and Vapors (Chemicals, Smells): Requires a Chemical Cartridge. These use activated carbon to chemically “adsorb” molecules from the air.

Note: Many environments require a Combination Cartridge that handles both particulates and gases.

Step 2: Decipher the Color Coding System

To make selection easier, international standards (NIOSH in the US and CE in Europe) use a universal color-coding system. Here is a breakdown of the most common CoSafety cartridge colors:

NIOSH (US Standard) Color Codes:

- Black: Organic Vapors (Solvents, degreasers, paint thinners).

- White: Acid Gases (Chlorine, hydrogen chloride, sulfur dioxide).

- Yellow: Organic Vapors + Acid Gases.

- Green: Ammonia or Methylamine.

- Purple/Magenta: P100 Particulates (99.97% filtration of all aerosols).

CE (EU Standard) Color Codes:

- Brown (A): Organic Vapors (boiling point > 65°C).

- Grey (B): Inorganic Gases.

- Yellow (E): Acid Gases.

- Green (K): Ammonia and derivatives.

Step 3: Check for Compatibility and Fit

A cartridge is only effective if it fits your mask perfectly.

- Universal Bayonet Connection: Most CoSafety masks and cartridges utilize a standard bayonet connection, ensuring they are compatible with other major industrial respirator brands.

- Dual vs. Single Cartridge: Half-face masks usually use dual cartridges to balance weight and lower breathing resistance, while some heavy-duty full-face masks may use a single, large canister.

Step 4: When Should You Change the Cartridge?

This is the most frequent question from procurement managers. There are three key “change indicators”:

- Sense of Smell or Taste: If you can smell or taste the chemical inside the mask, the cartridge is “saturated” and must be replaced immediately.

- Breathing Resistance: For particulate filters, if it becomes difficult to breathe, the filter is clogged with dust.

- End-of-Service Life Indicator (ESLI): Some advanced cartridges have a visual change, but most rely on a pre-determined Change-out Schedule based on the concentration of the hazard.

The CoSafety Advantage: Reliability for Wholesale

As a factory-direct supplier, CoSafety ensures that every cartridge is tested under rigorous laboratory conditions.

- Premium Activated Carbon: We use high-iodine value coconut shell activated carbon for superior adsorption capacity.

- Strict QC: Every batch is tested for airflow resistance and filtration efficiency.

- Bulk Availability: We maintain a steady stock of P100 and ABEK1 cartridges to support our global distributors in the USA, EU, and Middle East.

Exhibited Worldwide Every Year

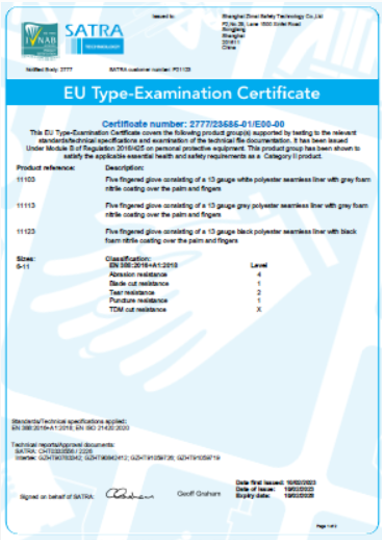

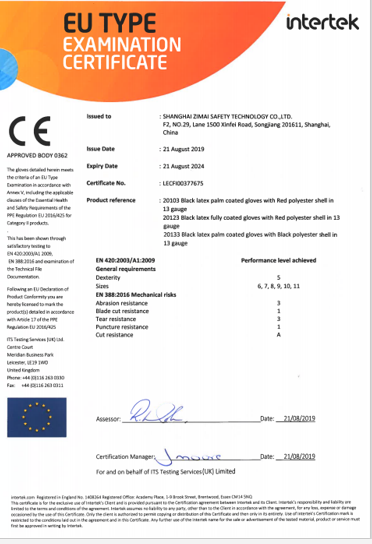

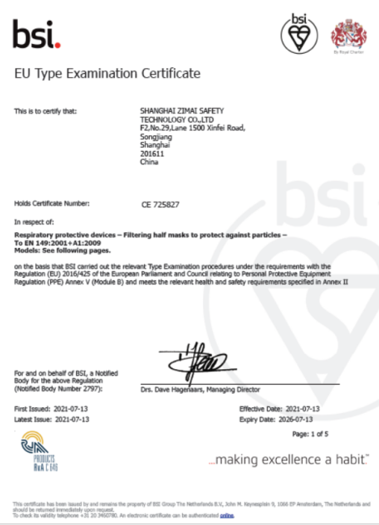

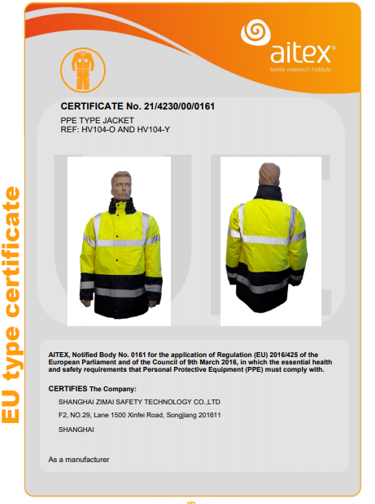

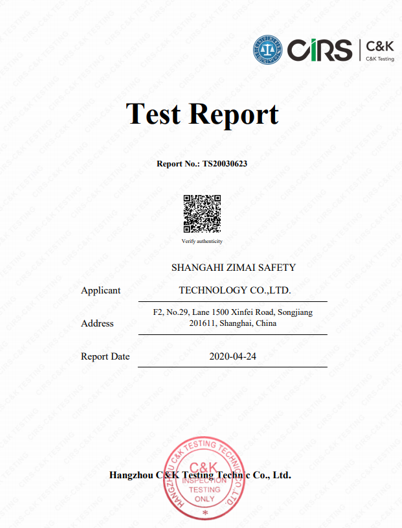

Certifications & Compliance

Order & Communication Process

Do You Have A Project To Discuss ?

-

Needs Assessment And Consultation

In this initial phase, we work closely with you to identify specific workplace hazards and safety requirements. Our team analyzes your industry standards (CE, NIOSH, ISO) to define the exact PPE specifications needed for your workforce.

-

Solution Proposal And Sampling

This stage involves presenting a tailored product solution, including material selection and customization options (OEM/ODM). We provide physical samples for your team to test, ensuring comfort, fit, and full compliance before moving forward.

-

Production And Quality Assurance

Once the sample is approved, mass production commences under strict ISO quality control protocols. We maintain transparent communication throughout the manufacturing process, conducting rigorous testing to guarantee every item meets safety certifications.

-

Global Logistics And Support

The final phase ensures seamless delivery through our global supply chain network. Beyond shipping, we offer after-sales support, including usage training and streamlined re-ordering processes to keep your inventory stocked.

FAQ

Answers to Your Questions About Facepiece respirator

Can’t find what you’re looking for? Please contact our professional sales manager.

Yes, compliance is our priority. All main products meet the mandatory standards for target markets (e.g., EU/US). We provide official certificates and technical data sheets (TDS) upon request and guarantee "Certificate Consistency" for every batch.

As a factory, we have greater flexibility and can customize products according to our customers' requirements. Since customization needs vary from customer to customer, the specific Minimum Order Quantity (MOQ) needs to be discussed based on the customer's specific requirements.

Yes, we provide full OEM/ODM services. We can customize packaging and apply your company logo.

We encourage samples to verify quality and fit suitability for your specific application before a bulk order.

Regarding after-sales service, if customers receive products with quality issues, please contact us immediately. We will compensate for the quantity in the next order, trace the root cause of the quality problem, and prevent the same issue from occurring in future orders.

Yes, we will not only provide relevant data sheet for customer training but also conduct video conferences to guide customers step by step in the safe and correct use of our products.